Steel and glass industries are high-stakes environments where temperature control and personnel safety are non-negotiable. Therefore, the need to manage extreme heat precisely becomes consequential.

Hot metal detectors detect the presence and movement of hot materials like molten steel or hot glass and allow for real-time process management. They are being rapidly installed in both industries because they reduce the risk of equipment damage, production errors, and workplace accidents.

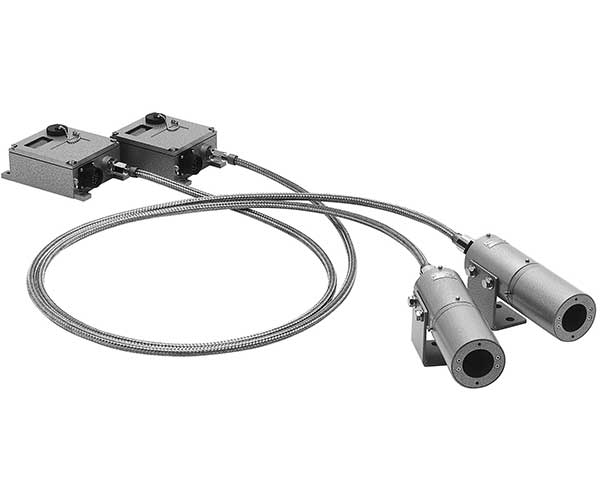

Therefore, Hokuyo has developed advanced hot metal detectors with versatile functionalities to meet the rising needs. The devices are engineered to withstand harsh and hot environments of both the steel and glass industries.

Key Application of Hot Metal Detectors in the Steel Industry

Hot metal detectors are commonly used in steel rolling and steel-making lines. Their deployment's purpose ranges from safety to production quality, emphasizing overall operational efficiency.

In the steel rolling lines, the key role of hot metal detectors is to:

Increase Operational Safety in Steel Mills

The PHV-10 series from Hokuyo delivers precise detection, even in the presence of steam or scale, triggering safety stops or automatically slowing when material deviates from its expected path.

Process Control Automation

Consistency and quality of metal are of utmost importance for every steel manufacturer as they influence the product’s performance. Hot metal detectors play a key role in automating the detection of product positions. They initiate timed operations such as cutting, rolling, or transferring with precision.

Therefore, when deployed at critical points across the production line, manufacturers can reduce human errors. Plus, ensure tighter tolerances and significantly cut down on scrap and rework.

Optimize Operations and Product Quality

Beyond automation and safety, hot metal detectors help maintain consistency and product quality throughout the production cycle. They track the temperature of steel during rolling to ensure that it aligns with process specifications.

The sensors also provide real-time data on the position of hot material to ensure every operation, from rolling to shearing and cooling, is completed with precise timing and alignment. Thus, the quality control becomes more optimized as dimensional inaccuracies, surface defects, and irregular cooling patterns can be avoided.

Continuous Reliable Production

Hokuyo's hot metal detector series is designed to withstand high-heat, high-dust environments with exceptional accuracy. They help with uninterrupted, high-speed processing of hot metal through their non-contact detection feature. The sensors maintain utmost precision even in the presence of mist, smoke, high dust, and airborne particles.

Hot Metal Detectors Application in the Glass Industry

Similar to steel manufacturing, the glass industry also deals with extremely high-temperature materials. Hot metal detectors are used for limited purposes, such as:

- Temperature monitoring: Hot metal detectors, such as Hokuyo’s PRV-10 hot metal detector series with an infrared detection cell, can monitor the temperature of molten glass in furnaces and also during forming processes like blowing, pressing, or drawing.

- Controlling processes: The real-time temperature data is used to adjust fuel flow, forming speeds, and other parameters to make sure the glass has optimal viscosity and is of high quality.

- Metal detection: During glass production, the hot metal detectors can be employed to detect the presence of hot metal fragments or other metal contaminants when paired with X-ray devices.

Key Features That Enable Versatility

- High temperature tolerance: Hot metal detectors are built to operate in extremely hot temperatures. For instance, Hokuyo’s PRV-10 series can detect heated materials with up to 1200°C temperatures accurately with a 5-msec or less response time (contactless detection).

- Non-contact sensing: Modern Hot metal detectors come with infrared technology to detect the presence and position of hot material without physical contact. Therefore, they can be used in fragile glass and rugged steel production processes.

- Faster response: They are crucial to optimizing the high-speed rolling mills and fast-moving glass forming lines process with their millisecond detection speeds.

- Compact and durable design: Hokuyo’s sensors are designed with flexible usability and endurance in mind. They can resist dust, scale, steam, glare, mist, and weather.

Choosing the Right Hot Metal Detector for Your Industry

Whether in the metal or glass industry, the role of hot metal detectors has become indispensable. Both demand rugged, responsive, accurate, durable, and precise temperature sensing to ensure safety as well as high product quality.

At Hokuyo, we understand these requirements and engineer advanced hot metal detectors to serve the purposes of these high-stakes industries. Whether you need reliable detection in rolling mills, casting lines, or glass production, we have a hot metal detector for every need.

Get in touch with us to learn more about hot metal detectors or to explore which one best suits your industrial needs

Factory Automation

Factory Automation Logistics Automation

Logistics Automation Process Automation

Process Automation Crane Collision Avoidance

Crane Collision Avoidance LiDAR Sensors

LiDAR Sensors Safety Laser Scanners

Safety Laser Scanners Optical Data Transmission

Optical Data Transmission Hot Metal Detectors

Hot Metal Detectors Laser Distance Sensor

Laser Distance Sensor Blog

Blog Whitepapers

Whitepapers Case Studies

Case Studies Infographics

Infographics