Factory Automation

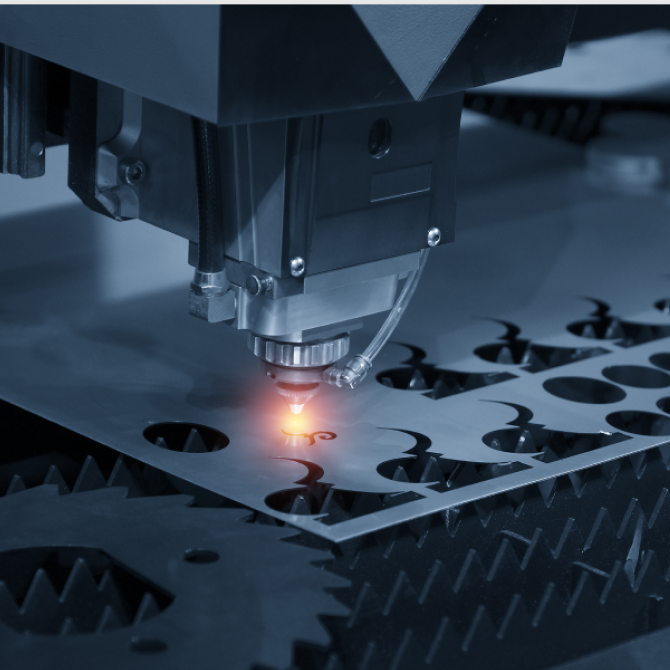

As a recognized sensor partner for the factory automation sector, Hokuyo's portfolio of product technologies encompass time-of-flight laser measurement, 2D and 3D LiDAR, and optical data transmission. For applications involving autonomous mobile robot guidance, weld-cell monitoring, material handling or wafer fabrication, our sensors enable a high degree of flexibility designed to match our customer requirements.

Logistics Automation

With the demand for greater automation in warehousing, ports and terminals through mobile material transport systems (AMRs, AGVs, RTGs) and overhead/gantry cranes, Hokuyo provides a broad range of sensors to improve performance, safety and increase overall efficiency. Whether the application uses fork-lifts, AS/RS, driverless or partially autonomous vehicles, our sensors are employed for navigation, positioning, measurement, obstacle detection, optical data transmission and safety.

Process Automation

The demand for sensors in the process industries is driven by production plants wanting to increase automation, improve product quality, enhance plant safety and improve energy and resource efficiencies. From monitoring industrial vehicles on mine sites for collision protection to detecting material flow in steel making, Hokuyo offers a wide range of sensors to ensure efficient and safe production and trouble-free processing.

FAQs

Quick answers to common questions about Hokuyo USA industry applications.

What industries does Hokuyo USA support?

What sensing technologies does Hokuyo provide for automation applications?

How do Hokuyo sensors help with factory automation?

How do Hokuyo sensors improve logistics automation in warehouses and ports?

What logistics automation functions can Hokuyo sensors support?

How do Hokuyo sensors support process automation and heavy industry?

How can I get help choosing a sensor for my industry or request a quote?

Have questions? Let's chat.

Factory Automation

Factory Automation Logistics Automation

Logistics Automation Process Automation

Process Automation Crane Collision Avoidance

Crane Collision Avoidance LiDAR Sensors

LiDAR Sensors Safety Laser Scanners

Safety Laser Scanners Optical Data Transmission

Optical Data Transmission Hot Metal Detectors

Hot Metal Detectors Laser Distance Sensor

Laser Distance Sensor Blog

Blog Whitepapers

Whitepapers Case Studies

Case Studies Infographics

Infographics