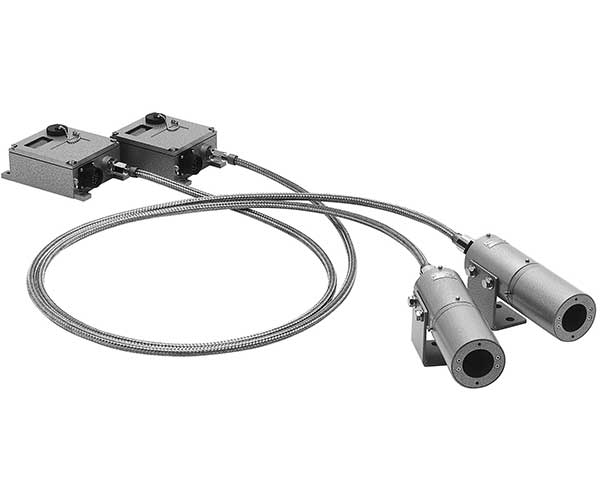

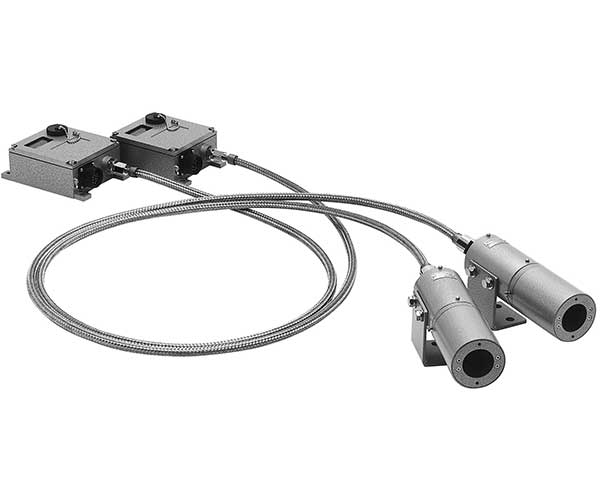

A hot metal detector from Hokuyo is the optimal solution for detecting infrared energy and other mill products.

Hokuyo hot metal detectors are robust, mill-duty sensors specifically designed for steel production applications. These devices are implemented wherever a process is to be controlled through accurate presence or position detection of material flow. Optical sensing solutions are used to detect the presence or position of rod, billet, bar, slab or plate in a rolling mill, continuous casting or other process lines. Any heated material that radiates infrared light or passes within the operating range of the hot metal detectors will initiate a primary or secondary function such as transfer of operations, pacing, slow down or a final stop control. These sensors can reduce the risks of process line failures, scrap and rework by enabling the user to accurately detect product from start to finish.

Hot Metal Detector FAQs

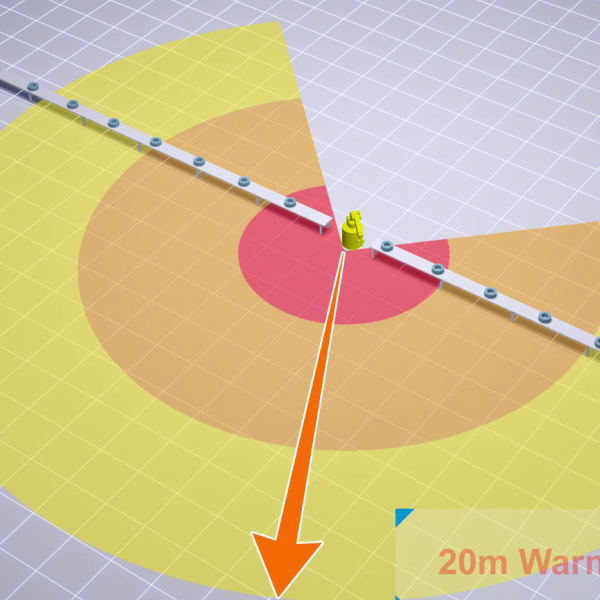

Unlike fixed guards or light curtains that protect only fixed areas, safety laser scanners provide flexible, 270° coverage. They can be reprogrammed for multiple zones, adapt to dynamic environments, and allow easier integration with automated systems.

Because they:

- Prevent accidents by monitoring hot materials in real time.

- Enable precise process automation (rolling, cutting, transferring).

- Protect equipment from overheating or misalignment.

- Reduce downtime, scrap, and production errors.

HMDs detect the infrared radiation emitted by hot objects above a certain temperature threshold. When the target material passes the detector’s sensing field, it triggers a signal for control systems to take action (e.g., start rolling, cut, stop, or transfer).

Depending on the series, Hokuyo’s HMDs can detect materials up to 1,200°C with response times as fast as 5 ms, making them suitable for high-speed rolling mills and glass forming lines.

- Non-contact detection for safety and durability.

- High resistance to dust, steam, scale, and harsh environments.

- Ultra-fast response times for accurate timing.

- Compact, rugged housings for easy integration.

- Reliable performance across steel and glass production.

- Steel mills (rolling, casting, forging).

- Glass manufacturing (molten glass monitoring, forming lines).

- Metallurgical operations requiring high-temperature process control.

Yes. Unlike photocells or mechanical switches, HMDs are unaffected by visible light, scale, or glare. They provide more reliable performance in the extreme heat and dust of steel and glass plants.

By detecting hot materials early and accurately, HMDs reduce the need for manual checks in hazardous zones. This minimizes risks of burns, accidents, and equipment collisions.

- Steel industry HMDs: Detects red-hot billets, slabs, and rods to control rolling and cutting.

- Glass industry HMDs: Monitors molten glass temperature, viscosity, and presence during forming processes.

Yes. They are designed with rugged housings and optical filtering to withstand dust, steam, and vibration. Regular cleaning of the optical window ensures long-term accuracy.

Factory Automation

Factory Automation Logistics Automation

Logistics Automation Process Automation

Process Automation Crane Collision Avoidance

Crane Collision Avoidance LiDAR Sensors

LiDAR Sensors Safety Laser Scanners

Safety Laser Scanners Optical Data Transmission

Optical Data Transmission Hot Metal Detectors

Hot Metal Detectors Laser Distance Sensor

Laser Distance Sensor Blog

Blog Whitepapers

Whitepapers Case Studies

Case Studies Infographics

Infographics