Industrial environments demand reliable, precise sensing to keep operations safe, efficient, and predictable. Whether it’s cranes lifting heavy loads, conveyors moving pallets, or automated equipment navigating tight spaces, knowing where something is - not just how hot it is - makes a critical difference.

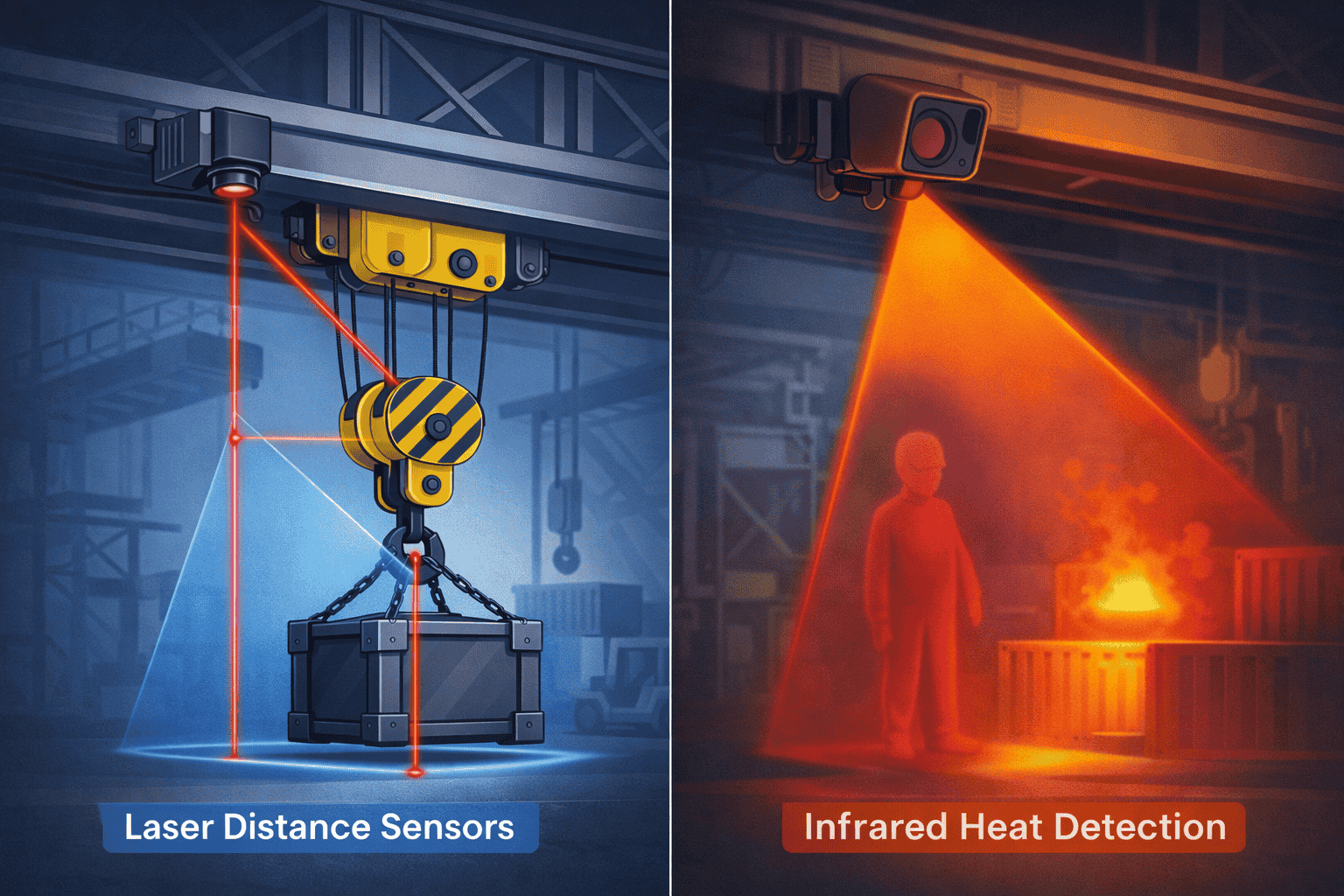

That's where the comparison between Laser Distance Sensors and Infrared Heat Detection begins.

Both technologies play important roles in industrial automation. But they solve very different problems. One measures exact distance and position. The other detects thermal energy and heat signatures. Choosing the wrong tool can lead to false readings, unnecessary downtime, or safety risks that could have been avoided.

Let’s break down how Laser Distance Sensors and infrared heat detection systems work, where each excels, and how to determine which technology best fits your application. From cranes and warehouses to ports and manufacturing floors, we'll explore real-world use cases, performance differences, and long-term operational impacts - so you can make informed decisions with confidence.

Understanding Laser Distance Sensors

Laser Distance Sensors use time-of-flight measurement to calculate how far an object is from the sensor. A laser pulse is emitted, reflected off a surface, and returned to the sensor. The travel time determines distance with millimeter-level accuracy.

Why Laser Distance Sensors Stand Out

- Measure exact position, not inferred conditions

- Maintain accuracy regardless of lighting

- Perform reliably on stationary or moving targets

- Enable continuous, real-time distance tracking

Unlike thermal systems, Laser Distance Sensors do not rely on heat signatures. This makes them ideal for applications where object presence, spacing, alignment, or clearance is the priority.

Unique Insight:

Many industrial environments assume thermal detection can replace distance measurement. In reality, temperature does not correlate with position - and relying on heat data for spacing or collision avoidance often creates blind spots.

How Infrared Heat Detection Works

Infrared heat detection sensors measure thermal radiation emitted by objects. Instead of calculating distance, they detect temperature differences between surfaces and surroundings.

Where Infrared Detection Is Useful

- Identifying overheating components

- Monitoring furnaces or molten materials

- Detecting abnormal heat buildup

- Fire prevention and thermal alarms

However, infrared sensors do not measure physical distance. Two objects at different distances but similar temperatures can appear identical to an infrared sensor.

Key Limitation:

Infrared detection struggles in environments where temperature is uniform - such as warehouses, ports, or conveyor systems - making it unsuitable for spacing, positioning, or collision prevention.

Accuracy and Reliability Comparison

Laser Distance Sensors

- Precision down to millimeters

- Stable readings across surface colors and lighting

- Unaffected by ambient temperature fluctuations

- Consistent performance in motion-based systems

Infrared Heat Detection

- Accuracy depends on surface emissivity

- Performance impacted by dust, steam, or reflections

- Cannot distinguish distance without triangulation

- Susceptible to false positives in warm environments

Unique Insight

In mixed environments where both heat and movement exist, relying solely on infrared detection often leads to over-alerting, reducing operator trust and system efficiency.

Application Comparison Across Industries

Cranes & Lifting Equipment

Laser Distance Sensors provide:

- Precise hook height measurement

- Load clearance monitoring

- Collision prevention with structures

Infrared detection:

Only useful for identifying overheated motors or brakes

Warehouses & Conveyors

Laser Distance Sensors ensure:

- Safe pallet spacing

- Accurate accumulation control

- Jam prevention

Infrared detection:

- Limited value unless monitoring overheating rollers

Ports & Heavy Equipment

Laser Distance Sensors support:

- Long-range object positioning

- Container alignment

- Safe crane navigation

Infrared detection:

- Detects hot machinery but not container distance

Safety and Automation Impact

Laser Distance Sensors directly support:

- Collision avoidance

- Safe stopping distances

- Predictable automation behavior

Infrared heat detection supports:

- Preventive maintenance

- Thermal fault detection

Unique Insight

Automation failures are rarely caused by temperature issues. They are caused by misjudged distance, speed, or clearance - areas where Laser Distance Sensors provide measurable control.

Environmental Performance

| Condition | Laser Distance Sensors | Infrared Heat Detection |

|---|---|---|

| Dust | High reliability | Reduced accuracy |

| Fog | Stable with filtering | Degraded |

| Sunlight | Unaffected | Can cause false readings |

| Temperature swings | No impact | Directly affects readings |

Cost, ROI, and Long-Term Value

Laser Distance Sensors:

- Reduce collisions and downtime

- Improve throughput consistency

- Lower maintenance caused by impacts

- Support scalable automation upgrades

Infrared detection:

- Prevents heat-related failures

- Limited ROI outside thermal monitoring

Unique Insight

Distance errors cause immediate damage. Heat issues develop over time. For operational uptime, distance sensing delivers faster ROI.

Infrared heat detection excels at identifying temperature anomalies and preventing thermal failures. But when it comes to automation safety, positioning accuracy, collision avoidance, and efficiency, Laser Distance Sensors deliver the clarity modern industrial systems demand.

Cranes need to know load height. Conveyors need exact spacing. Automated equipment needs reliable distance data - every cycle, every shift, every environment. Temperature alone cannot provide that certainty.

Laser Distance Sensors enable predictable automation, safer operations, and higher throughput by eliminating guesswork. They turn motion into controlled movement and uncertainty into measurable data.

As industries continue to automate, the demand for precise, non-contact distance measurement will only grow. Facilities that invest in accurate sensing today build safer, more resilient operations tomorrow.

If your application depends on knowing where something is - not just how hot it is - Laser Distance Sensors are the technology that keeps operations moving forward with confidence.

Factory Automation

Factory Automation Logistics Automation

Logistics Automation Process Automation

Process Automation Crane Collision Avoidance

Crane Collision Avoidance LiDAR Sensors

LiDAR Sensors Safety Laser Scanners

Safety Laser Scanners Optical Data Transmission

Optical Data Transmission Hot Metal Detectors

Hot Metal Detectors Laser Distance Sensor

Laser Distance Sensor Blog

Blog Whitepapers

Whitepapers Case Studies

Case Studies Infographics

Infographics