Rolling mills operate in a high-speed, high-risk environment due to the processing of hot metal. Therefore, not only is there a risk to workers' lives, but the equipment also faces a significant danger of failure or permanent damage if hot metal spills on it.

Any of these issues can lead to stagnation in steel processing, hampering your business objectives. So, how can you overcome this problem and make rolling mill operations more efficient?

The deployment of a hot metal detectors (HMD) can improve the workflows at rolling mills. With better visibility and control over hot metal processing, rolling mills can maintain consistent output quality, increase throughput, and complete business objectives on time.

The Rolling Mill Process

The steel rolling mill process involves decreasing the thickness of a material by passing it through a series of heavy rollers. It can be compared to rolling dough through a rolling pin. Just like dough flattens and spreads, steel undergoes a similar process when intense pressure from the rollers is applied.

Rolling enhances the material’s strength, surface finish, uniformity, and dimensional accuracy. Steel slabs or billets are fed into the rollers under high pressure to mass produce metal sheets, bars, and structural components.

Additionally, rolling is executed at a room temperature (cold rolling) or high temperature (hot rolling), depending on the required finish and mechanical properties. Hot rolling is performed above the steel’s recrystallization temperature, facilitating easy shaping and higher quantities.

However, cold rolling is performed below the recrystallization temperature to produce smooth, tighter tolerances and comparatively much stronger products.

How Hot Metal Detectors Can Improve Efficiency?

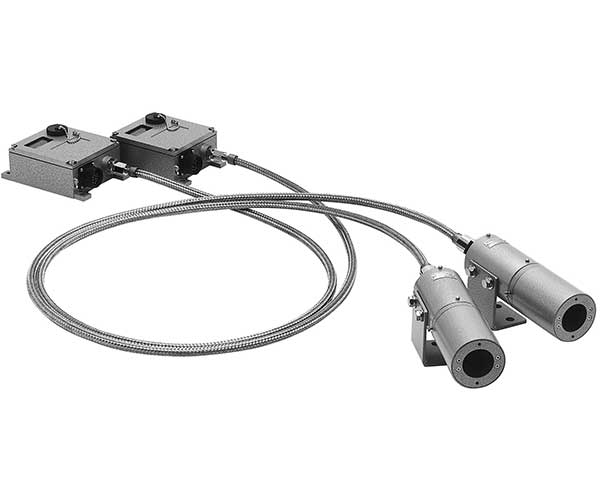

The Hokuyo LAV-10/11 series hot metal detectors are designed explicitly for this purpose. Using it improves the efficiency of rolling mills as it helps with:

Consistent Product Quality

Hot metal detectors consistently measure the heat of steel to ensure the correct temperature is maintained. This helps produce a final product with a uniform grain structure, which results in better steel strength, ductility, and overall finish. Accurate temperature control also helps uphold consistent metallurgical properties across batches.

Reduced Energy Consumption

HMDs provide real-time presence signals that prevent overheating of the metal. This leads to more efficient heat usage, reduced energy waste, and extends the life of equipment. The LAV series from Hokuyo can provide real-time heat data on metal temperatures, reaching up to 200 °C.

Streamlined Operations

In hot rolling, there are three phases: pre-heating, shaping, and cooling. These phases rely on accurate thermal control, and manually performing them takes considerable time. Hot metal detectors can streamline this process by automatically collecting real-time temperature data, enabling immediate adjustments. This also results in improved flow of the hot metal, better shape accuracy, and better process coordination.

Proactive Equipment Maintenance

The parts and other equipment used in rolling mills can indicate malfunctions due to sudden temperature fluctuations. Continuous malfunctions can lead to permanent failure and halt operations. HMDs are designed specifically to overcome these issues as they help maintain an optimal temperature. Therefore, no sudden temperature changes and no parts or equipment failures.

Safer Work Environment

As hot metal detectors reduce reliance on humans, the likelihood of mishaps decreases significantly. Furthermore, HMDs, such as Hokuyo’s LAV series, are designed for environments with high temperatures, dust, steam, and vapor, allowing workers to avoid risking their health by periodically checking the temperature. HMDs also minimize the risk of overheating-related accidents, such as spillage or metal deviating from the desired path, which can result in wasted time and money.

Benefits of Advanced Hot Metal Detection

Rolling mills deal with high-temperature metals, and not all types of hot metal detectors can withstand such harsh environments. However, the optical fibre hot metal detectors, such as LAV-10/11 series, excel in such conditions. It’s because of their heat-resistant fibre cables and heavy-duty sensor heads, making them durable as well as accurate.

Minimize Scrapping

HMDs can accurately identify the presence and position of hot material in real-time once they detect the infrared light radiated by the metal. Therefore, they help maintain process integrity across different rolling stages. This precision eliminates misfeeds, incorrect timing, rolling errors, spillage, or metal flow deviation, all of which are common causes of product rejection. Minimizing such faults means less material waste, reduced rework, and savings in operational costs.

Boost Productivity

With HMDs equipped in rolling mills, real-time feedback and adjustments can be made promptly, thereby increasing the pace of production. Furthermore, the increased sense of safety among personnel also boosts their morale, leading to improved performance.

Reliable Operations in Harsh Conditions

Unlike conventional metal sensors, fibre optic detectors function reliably in high temperatures and are immune to electromagnetic interference. Therefore, they don’t malfunction due to loud noises from other heavy machinery. This results in uninterrupted rolling mill performance and timely project completion.

Improved Line Automation

Hokuyo’s hot metal detector series can automate systems and trigger actions such as transfer of operations, pacing, slowing down, or a final stop control. Plus, their accurate detection ensures seamless coordination between processes like descaling, shearing, rolling, and cooling.

Hokuyo’s Hot Metal Detectors Improve Productivity and Safety

The high-temperature, dust-filled, harsh environments of steel production plants make rolling mill operation challenging. The hot rolling process is especially challenging to manage because it requires continuous temperature monitoring of the material. Doing so manually not only consumes time but also risks the lives of workers.

At Hokuyo, we dedicate ourselves to streamlining and easing the rolling mill operations by engineering advanced hot metal detectors. We have used the state-of-the-art fiber optic technology that can withstand extreme temperatures while providing fast and accurate data. We strive to provide safe, precise, and durable industrial solutions.

Learn more about hot metal detectors and determine which suits your requirements best.

Factory Automation

Factory Automation Logistics Automation

Logistics Automation Process Automation

Process Automation Crane Collision Avoidance

Crane Collision Avoidance LiDAR Sensors

LiDAR Sensors Safety Laser Scanners

Safety Laser Scanners Optical Data Transmission

Optical Data Transmission Hot Metal Detectors

Hot Metal Detectors Laser Distance Sensor

Laser Distance Sensor Blog

Blog Whitepapers

Whitepapers Case Studies

Case Studies Infographics

Infographics